Netting from Mørenot

Premium quality netting is crucial for a solid aquaculture net. We are dedicated to maintain a high and stabile quality and the production process is closely monitored all the way from filament to finished product.

NET DESIGN

Mørenot Aquaculture manufactures nets for fish farming based on the customers requirements, conditions on the sites and operational equipment and methods.

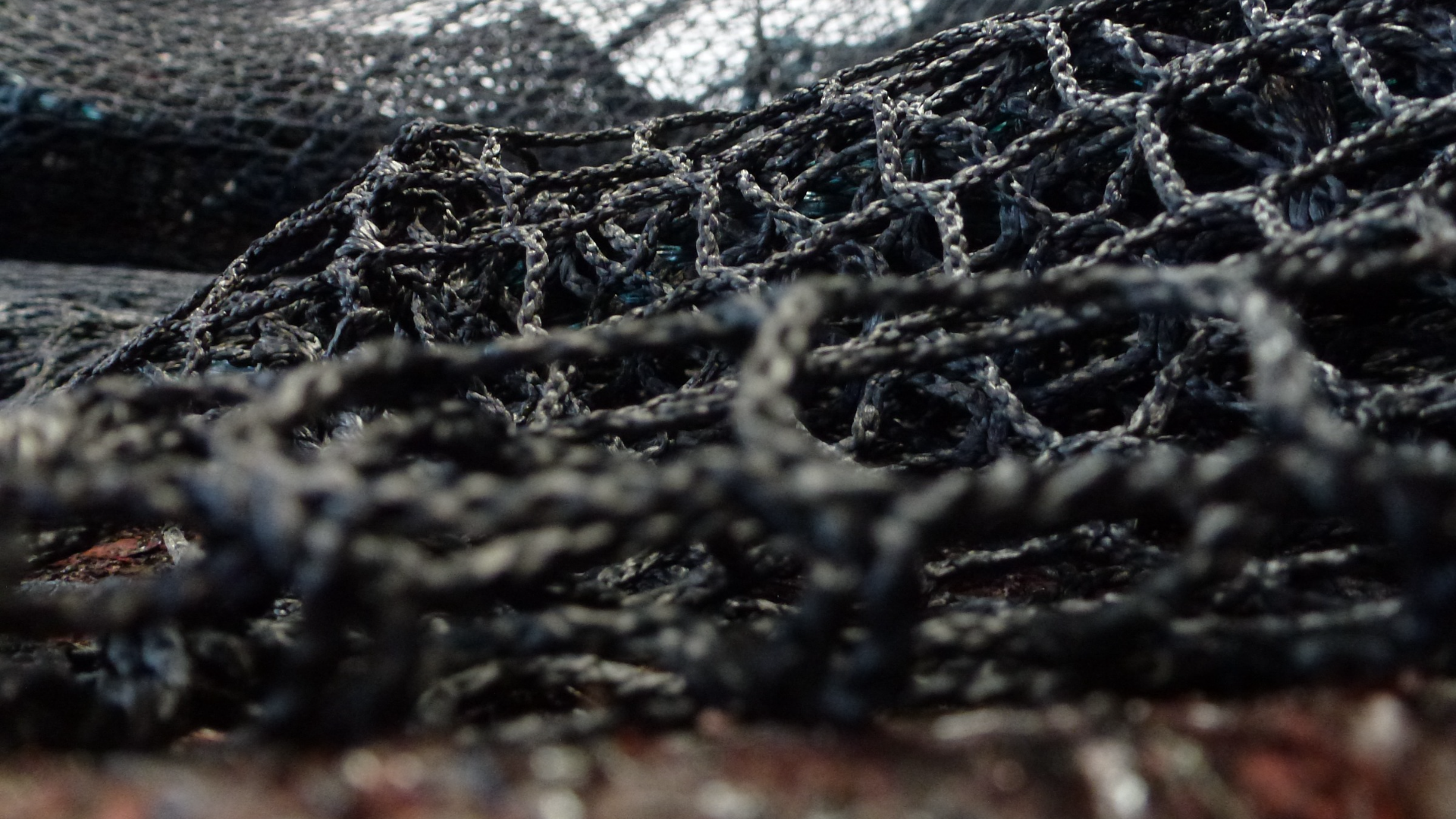

NETTING

Netting from Mørenot Aquaculture is well known through out the industry for high quality.

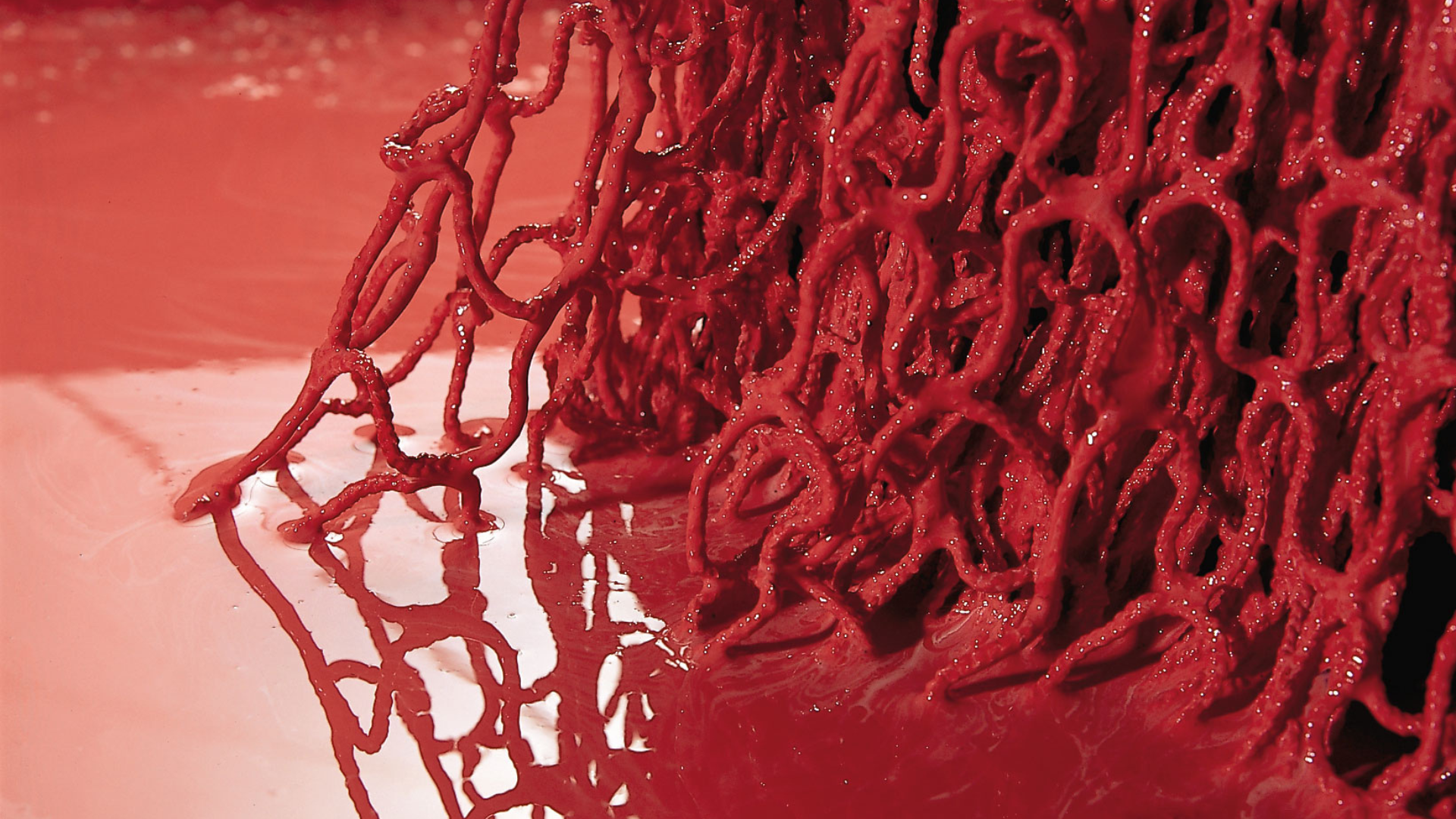

ANTIFOULING AND COATING

Mørenot Aquaculture customizes nets for adaptation to each customers requirement with smart solutions for easier handling and maintenance of nets.

Nylon

Ripple free

We were the first Norwegian net producer to offer ripple-free, knotless netting. We can produce most types of nets in a variety of fibers. Our nets keep a very high strength and at the same time low weight.

Raw material

Our nettings keep a very high tensile strength relative to the twine thickness and weight. We use only premium quality filament from Nylon, HMPE and HDPE.

Production process

The whole production process is closely monitored and the quality is tracable all the way back to each filament supplied. We thereby manage to maintain a constant, high quality of our nettings. The production process is monitored according to ISO 9001:2008. All our net solutions follow the NS 9415 (Norwegian Standard).

Mørenot nets design

We can deliver customized solutions, optimized in relation to managing and operating methods. The groove solutions comply with the requirements of Norwegian Standard 9415, and are assembled at our branches in Norway, Lithuania, Canada, Scotland, Shetland and Spain. We supply nets in all types of material; Nylon, HMPE (Dyneema), HDPE and Multi Mono Nylon.

SATISFIED BREEDER

The farming company Arnøylaks has 4 licenses in Nord-Troms. They say that their salmon is top-trained and firmly attached to the fish, because it has grown under natural conditions in the strong-current Lauksundet.

Arnøylaks was one of the first breeders to use the Flexilink® system in 2013 - and with great success. At its most exposed location, in Skjervøy, which is exposed to strong currents and large wave movements, Flexilink® now ensures 3rd generation in this facility.

Håvard Høgstad is CEO at Arnøylaks, and says that even after 5 years in the sea, the mooring shows no signs of wear. They have only had local adaptations and modifications when they have made adjustments to the plant in general. Therefore, they are now considering a new Flexilink® system, for another exposed location.

International Sales - Cold Water

Casper Guldberg Petersen

Torben Henriksen

Nina Hildre

International Sales - Warm Water

Jordi Comas Morte

Abdessalem Amougar