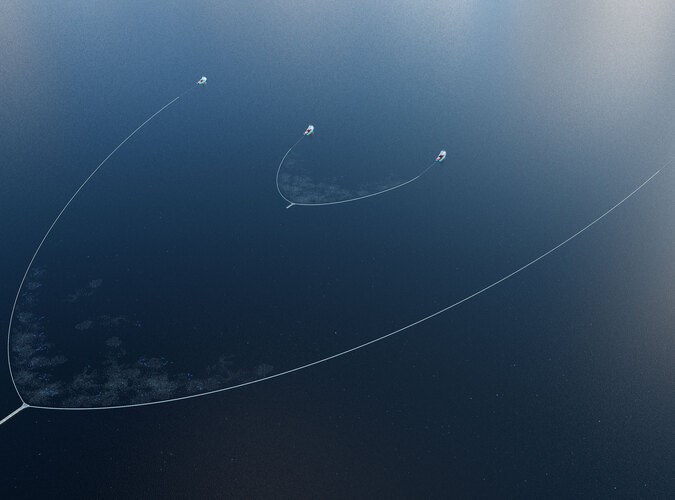

Mørenot Aquaculture, Lift-Up, Aquapro and Ragn-Selles Havbruk are launching a cage system at Aqua Nor 2021 which collects and reduces the accumulation of sediment in fish farm locations and reuses this waste as biofuel. Full-scale testing at Lerøy Seafood shows a 60-70 per cent collection performance, which offers major environmental benefits and good production utilisation.

“In addition to helping overcome environmental challenges, weight has been given to developing a cost-effective solution which doesn’t require substantial investment or new ways of working and operating,” explains Yngve Askeland, R&D manager at Mørenot Aquaculture AS.

Accumulation of sediment from excretion, feed residues and heavy metals released when spraying impregnated cage meshes is not just a challenge, but can also turn areas in dead zones over time and thereby limit maximum permitted biomass (MPB).

“In cooperation with Lift-Up, we’ve by and large found a good solution to this,” reports Askeland.

Tested

The solution has been tested in cooperation with Lerøy Seafood, and Askeland emphasises the importance of verification and documentation. He is very satisfied with the results achieved at the test location.

“A 60-70 per cent reduction in sediment will be highly significant, both for the environment and for how much salmon Norwegian fish farmers can serve to the world’s population.”

Helps

Lerøy Seafood is well satisfied with trends in the pilot phase, and believes this could be a system which helps to overcome challenges posed by sludge while also reusing the waste as renewable energy.

“We’ve committed to meeting a number of the UN’s sustainable development goals, and are working continuously on how we can be as sustainable as possible,” says Nina Møgster at Lerøy Seafood. “This is a good example of collaboration and tailoring of equipment and technology to meet both operational and environmental challenges.”

Integration

The revised edition of the NS 9415 standard, which comes into effect this autumn, specifies new requirements for system integration in Norwegian aquaculture.

“We’ve further developed a product which is well known and has been tested in the fish farming sector over many years,” reports Jarle Ragnhildstveit at Lift UP AS.

“Through our collaboration with Mørenot Aquaculture, we’ve met the requirements in the new standard for better integration of technical equipment. The fish farmer will get a complete system where the components are developed to fit together and have the same purpose. This will be a sought-after solution.”

Criteria

A concentration on overcoming environmental challenges and creating good fish welfare will be an important criterion when Mørenot Aquaculture comes to optimise existing products and services or develop new solutions for the fish farming industry.

“Material choice and configuration of the net cage are carefully planned to ensure good water throughflow and the best possible fish welfare, while also functioning effectively as a sludge collector,” says Askeland.

“In addition, the waste is converted into renewable energy and fertiliser with the aid of Ragn-Selles’ logistics solution. It’s thereby utilised as a resource and makes a positive contribution to the circular value chain.”

Further information from

Yngve Askeland Jarle Ragnhildstveit

Aqua Knowledge AS Lift-Up AS

M: +47 922 87 224 M: +47 977 11 719