In an ongoing collaboration with a third-party company in Denmark, Mørenot has initiated a project to investigate the increased circularity of the Hvalpsund cages - how to recycle end-of-life pens into new ones. Per today, Mørenot can offer walkways of 50 % recycled plastic. However, there is an ambition of increasing the percentage of components to be developed from recycled plastic, starting with the other non-critical parts.

End-of-life pens as a resource for new production

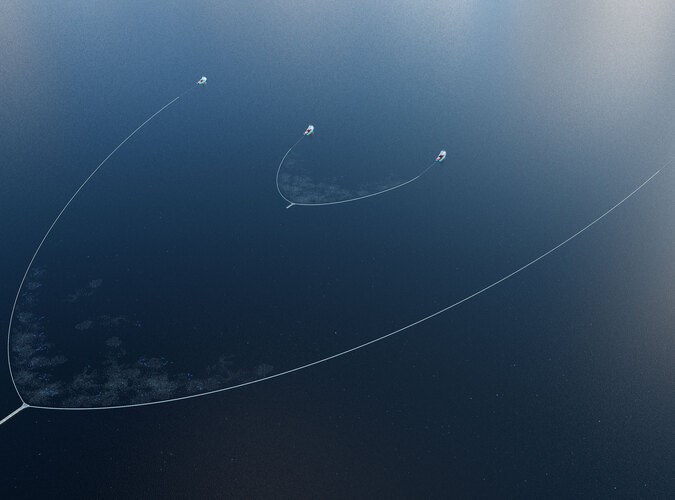

On the picture below you can see the process during which used pens can be recycled and utilized as a new resource. Once a pen is ready to be replaced, it is taken ashore where it is cut, its parts separated, before it is washed onsite. Thereafter, the parts are transported to Mørenots partners in Denmark, where the plastic is washed, grinded, and pelletized into granules. The granules can now be repurposed in new products. In this case, the granules are mixed in with new HDPE for production of walkways. The end-state of this process is of course when the recycled material is back in the sea.

The purpose of this project is to increase the resource productivity of the product and to increase the lifetime of the plastic that is used in the production of cages.

"It is important for Mørenot to take responsibility and contribute to a more sustainable production," says Casper Guldberg Petersen, Head of Cages at Mørenot Aquaculture. He believes there is only one way forward: "We must ensure responsible management of the plastic: that it’s not treated as waste, but rather as a resource into new production. We must be able to document that we take care of the materials to the best of our ability, and that we recycle. We believe this is the only way moving forward", says Guldberg Petersen.

Casper Guldberg Petersen, Head of Cages

Per today Mørenot is only able to use recycled HDPE in the non-critical parts of the cages. However, with the goal of increasing the amount of recycled material to be used in the final cages, Mørenot is in dialogues with suppliers to see whether they can come up with a solution for using recycled HDPE in production of new pens as well. This will of course require that the recycled plastic is of good quality and that the pureness of the material is high.