Mørenot Collect, a cage system from Mørenot Aquaculture which collects and reduces sediment accumulation at aquaculture locations, has documented a collection effect of about 60 per cent through full-scale testing at Lerøy Sjøtroll. The sludge is converted to green energy, corresponding to the annual power consumption of 40 households. This shows how the shift to a circular economy can reduce the environmental load.

New operating standard the ambition

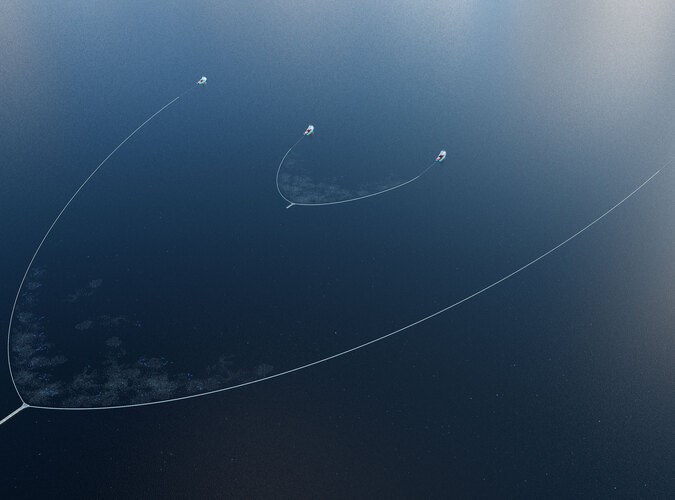

Lerøy Seafood has tested Mørenot Collect since August 2020, covering a whole generation of rainbow trout at the Blom fish farm in the Oster Fjord. This steel facility, with 14 cages each measuring 25 x 25 metres, has a maximum permitted biomass (MPB) of 3 120 tonnes. The test has documented a solid collection effect estimated at about 60 per cent of the particulate discharge, which is converted to green energy and fertiliser at the other end.

The upside is so substantial that the fish farmer now wants to verify and adapt the cage concept to today’s traditional operation and locations. Lerøy Seafood is due to get the very first collector cage – measuring 160 metres in diameter – from Mørenot in the water during April.

“We want to adapt the cage concept technically and operationally to our traditional farm with 160-metre cages,” explains Sven-Åge Hauge, project manager for aquaculture technology development at Lerøy Sjøtroll. “The trial has shown substantial environmental gains.”

Marthe Amundsen Brodahl, responsible for sustainability at Mørenot, reports that the collection cage is one of the contributions the company has been working on in recent years.

“We’ve committed to several of the UN sustainable development goals, and are working continuously on solutions which can help to harvest the sea’s resources more sustainably,” she says. “So it’s particularly pleasing when a player like Lerøy reports a substantial effect from the collection and circular opportunities this concept offers.”

Optimal for fjord locations

Mørenot Aquaculture’s cage concept has proved a good option for minimising fish-farm impact on the local environment, particularly in fjords where water circulation can be low at times. Although the Norwegian coast has many deep fjords and a northerly current which helps good water turnover, challenges related to the deterioration of seabed fauna can arise.

An investigation in the immediate vicinity of the fish farm (MOM B) shows that the environmental standard is good, and Lerøy accordingly sees the collection cage as a possible solution for pursuing even more sustainable aquaculture.

Reducing discharges and maintaining good fish welfare form the basis for sound and healthy food production in Norway’s fjords, in parallel with maintaining good and secure jobs in local communities.

Lerøy Seafood has, since August 2020, tested Mørenot Collect through an entire generation of rainbow trout at their location Blom in Osterfjorden.

350 tonnes of waste

During the test period, the collection cage gathered 350 tonnes of sludge (100 per cent dry matter), which will be converted to renewable energy and fertiliser using the Framo Lift-Up technology and the Ragn-Selles Havbruk logistical solution.

The cage thereby functions as an effective sludge collector and provides substantial circular opportunities.

“The dry matter collected at the farm provides about 800 000 kilowatt-hours of renewable energy,” observes product developer Jarle Ragnhildstveit at Framo Lift-Up. “That corresponds to power consumption by 40 Norwegian households for a whole year.”

More information from

Mørenot

Marthe Amundsen Brodahl

Strategy and business development manager

Mobile: +47 452 39 596

Framo Lift-Up

Jarle Ragnhildstveit

Product developer

Mobile: +47 977 11 719

Mørenot Collect is a fish-farm cage system which collects and reduces the accumulation of sediment at aquaculture locations, and reuses this waste as biofuel. It is the result of a collaborative project between Mørenot Aquaculture, Framo Lift-Up, Aquapro and Ragn-Selles Havbruk, and has been tested in collaboration with Lerøy Seafood. The system has been developed to provide compatibility, and satisfies the new requirements in Norwegian standard NS 9415 for system integration in Norway’s aquaculture sector.